Newsletter 2014.11 Index

Theme : "Mechanical Engineering Congress, 2014 Japan (MECJ-14) Part 1"

|

Error Factors and Important Reminders in the Air-flow Measurements

Osamu Terashima

|

Abstract

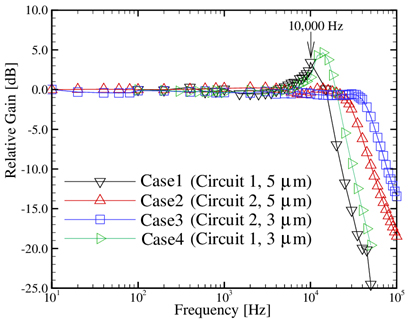

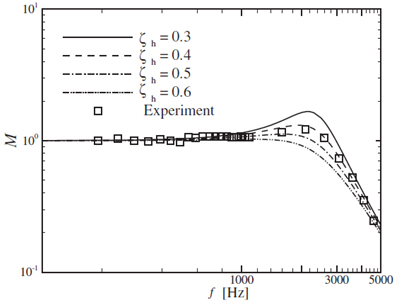

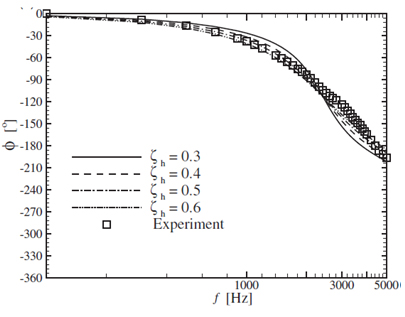

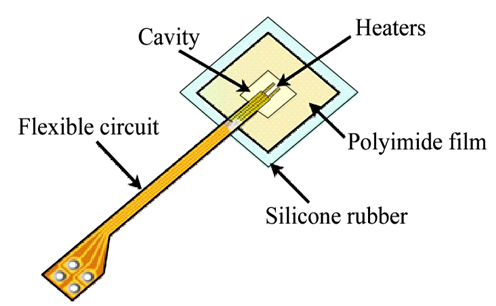

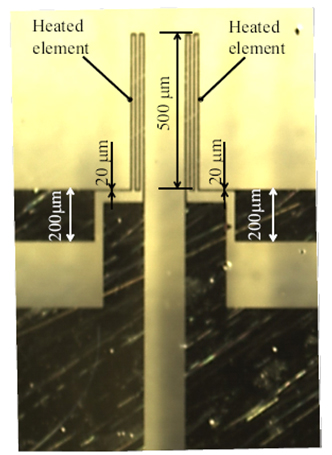

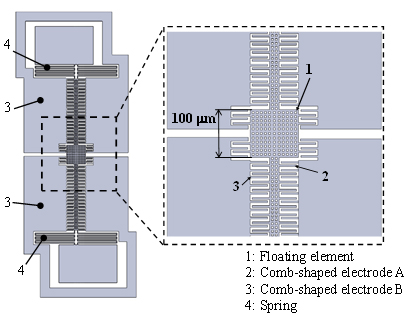

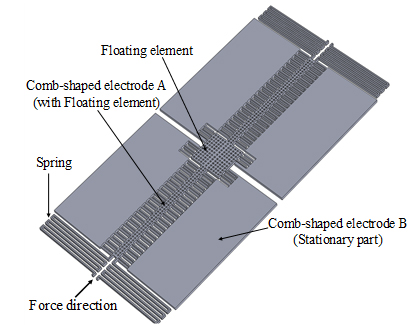

In this work shop, the error factors and important reminders in the air-flow measurements are presented. Firstly, those in the measurement of the velocity by means of the hot-wire anemometry is shown. In the measurement of the velocity fluctuation by HWA, frequency response of the HWA is very important and it requires considerable attention. It depends on not only the temperature of the air-flow but also for the electrical circuit of the HWA and the diameter of hot-wire. Secondly, those in the measurement of the pressure fluctuation by means of the pressure probe is shown. The frequency response of the pressure probe in the pressure fluctuation measurement is decreased by the occurrence of the Helmholtz and Organ-pipe resonances. Therefore, in the pressure fluctuation measurement, the preliminary experiment to check the frequency response of the pressure probe is needed. Finally, those in the measurement of the wall-shear stress with the micro-fabricated hot-film and floating-element sensors are shown. In the measurement with the micro-fabricated hot-film sensor, we should take account with the heat capacity of the substrate which causes the decrease of the frequency response. In addition, static electricity and electrical noise to be paid attentions because they cause the decrease of the measurement accuracy with the floating-element wall-shear stress sensor.

Key words

Flow Measurement, Error Factor, Hot-wire Anemometer, Pressure Tube, Wall-shear Stress Sensor

Figures

Fig. 1 Frequency response of HWA

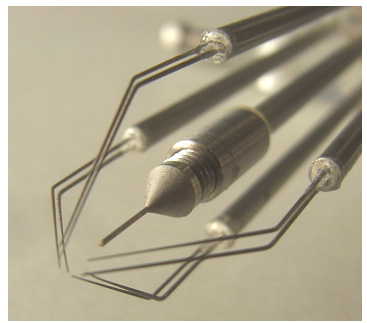

Fig. 2 Photograph of the probe for the measurement

of three components of velocity

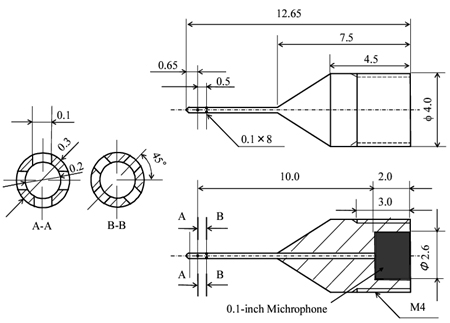

Fig. 3 Schematic view of the pressure probe

Fig. 4 Amplitude ratio of the measured pressure fluctuation by the pressure probe

Fig. 5 Phase difference of the measured pressure

fluctuation by the pressure probe.

Fig. 6 Perspective view of the Hot-film sensor

Fig. 7 Photograph of the heaters of the Hot-film sensor

Fig. 8 Top view of the Floating-element sensor

Fig. 9 Perspective view of Floating-element sensor