Newsletter 2017.2 Index

Theme : "The Conference of Fluid Engineering Division"

|

Research on amorphous actuators utilizing liquid crystal flows

Rinko MATSUDA

|

Abstract

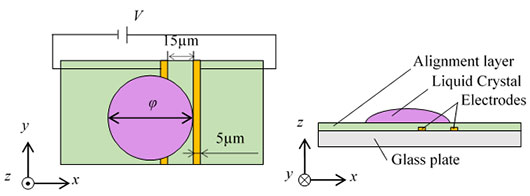

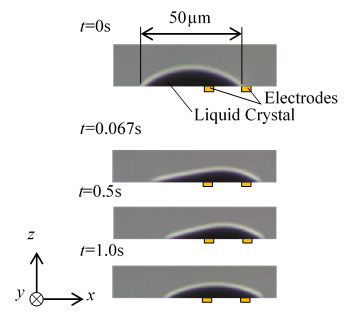

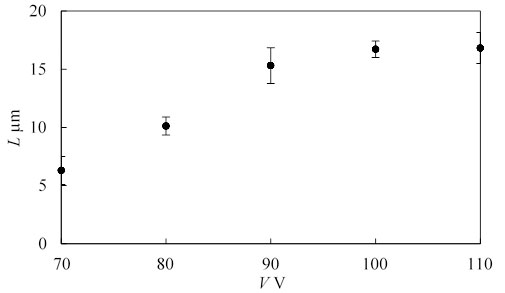

To develop the amorphous liquid crystalline actuators which can drive objects as well as can change own shape, the behavior of a liquid crystal droplet under electric fields has been investigated. Figure 1 shows the schematics of an experimental setup. The liquid crystal droplet is placed on a glass plate. A pair of electrodes and an orientation layer which anchors the rod-like liquid crystal molecules to be perpendicular to the plate are treated on the glass plate. The behavior of the liquid crystal droplet when a transverse electric field is applied to the droplet is observed and analyzed. Figure 2 shows the time series of observed microscope images. The diameter of the droplet is 50µm, and the voltage of 90V is applied between the electrodes for one second. Just after the application of the voltage, the droplet starts spreading toward the right electrode, displacing its position also toward the electrode. While the shape of the droplet returns to its original shape, the displacement of the droplet remains after the release of the voltage. Figure 3 shows the effect of applied voltage on the displacement of the liquid crystal droplet. The displacement increases with the increase of the applied voltage and the maximum displacement is found to be 17.5µm which is equal to the distance between the original position and the center of the electrodes. We have also attempted to the liquid crystal droplet under a vertical electric field, and the successive drive of the droplet is observed for this case.

Key words

Liquid Crystal, Droplet, Actuator, Electric Field

Figures

Fig. 1 Schematics of an experimental setup

Fig. 2 Motion of liquid crystalline droplet under transverse electric field

Fig. 3 Dependence of actuator displacement on imposed voltage