Simulation of the opening delay by the oil film stiction in the compressor valve

|

|

|

|

|

|

Fumitaka YOSHIZUMI*, Yasuhiro KONDOH*, Takahiro MOROI**, *Toyota Central R&D Labs., Inc., System & Electronics Engineering Dept. I, 41-1, Yokomichi, Nagakute, Aichi, 480-1192 Japan

|

||

Abstract

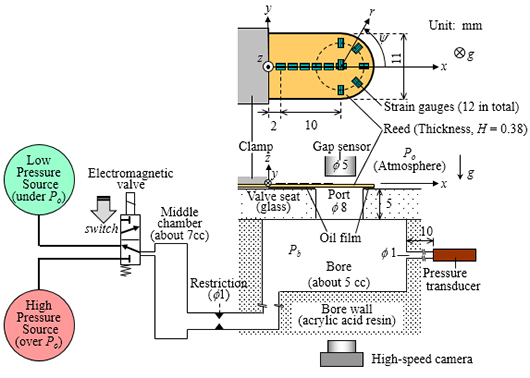

There exists the opening delay in reed valves due to the stiction force of the oil film between the reed and the valve seat. That is, the oil film undergoes the negative squeeze motion through the elastic deformation of the reed, and generates the negative pressure in the oil film resulting in the stiction force. The negative pressure yields cavitation in the oil film as observed in the experiment of the valve opening delay by the authors (1) (the setup is shown in Fig. 1). The stiction force is expected to be strongly influenced by cavitation in the oil film.

The authors have proposed a simulation algorithm for the valve opening delay in which the reed deformation, the gas flow and the oil film flow are coupled, in order to reproduce the experimental delay time [see Ref. (2) for details]. In the algorithm, the cavitation model and the blow-by (oil film rupture) model are newly developed. The cavitation model (herein called the dynamic cavitation model) simulates the expansion of cavitation bubbles directly. This model is capable of expressing the tensile stress in liquid, i.e., the oil film pressure below the vacuum pressure. The features of the cavitation model are as follows:

- the new variable β – the fraction of liquid in the time rate of the oil film volume – is defined to quantify the bubble expansion effect in the film pressure,

- the dilatational viscosity of the bubble (3)-(5) is introduced to simulate the tensile stress duration of the order of 10 ms.

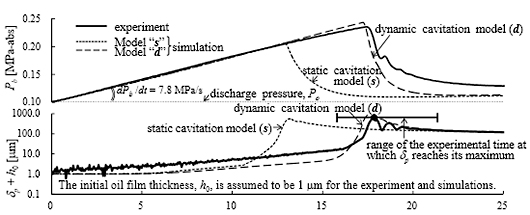

The comparison of the simulation and the experiment indicates the need to take into account the tensile stress in the oil film. The conventional cavitation model (the Reynolds condition), in which the lower limit of the oil film pressure is set to the absolute zero (the vacuum pressure), gives the delay time shorter than the experiment (Fig. 2, Model “s”). The dynamic cavitation model allowing the tensile stress in the oil film reproduces the experimental delay time (Fig. 2, Model “d”). The obtained β in the dynamic cavitation model indicates that the bubble expansion prevents the film pressure from falling and limits the tensile strength.

The simulation well reproduces the oil film behavior in the experiment. In the stage just before the blow-by (rupture) of the oil film, the void fraction distribution is in good agreement with the cavitation region in the experiment (Fig. 3). The transient of the blow-by region in the simulation is also in good agreement with that in the experiment (Fig. 4).

Furthermore, the present simulation can also capture the effects of experimental parameters, such as the contact area between the reed and the seat, and the time rate of the bore pressure increase (6), and allows understanding the mechanism of the valve opening delay.

Keywords

Compressor, Valve, Oil Film, Cavitation, Tensile Stress in liquid, Coupling Problem

Figures

Fig. 1 Experimental setup for the valve opening delay

Fig. 2 Reed displacement at the port center (δp) and the bore pressure (Pb)

|

|

Fig. 3 Cavitation in the oil film

[left: the oil film image in the experiment, right: the void fraction by the simulation, both animation shows transients for 1.4 ms just before the blow-by (rupture) of the oil film.]

|

|

Fig. 4 Blow-by (rupture) of the oil film

[left: the oil film image in the experiment, right: the blow-by region in the simulation (shown by red), both animation shows transients for 0.6 ms.]

References