Nano powder transportation by combining plasma actuation and electrostatic mixing in a tube

|

||||||||

Abstract

Recently, the particulate matter included in the exhaust gas from automobile and factories has been paid attentions as one of the emerging environmental problems. The regulation for the SPM or PM 2.5 exhaust is now becoming more strict every year. Especially, nano sized particles in the vehicle exhaust fumes bring more serious damage to human health because nano sized particles have higher risk to be deposited on lung alveoli. The innovative technology for the collection of fine or ultra fine particles and surface purification of contaminated particles has been demanded from industries intensively. Furthermore, in a material processing, the choking of the powder transportation tube often occurs for ultra fine powders of several tens of nano meter due to agglomeration of powders on the tube wall. The efficient transportation of ultra fine powders is also strongly required.

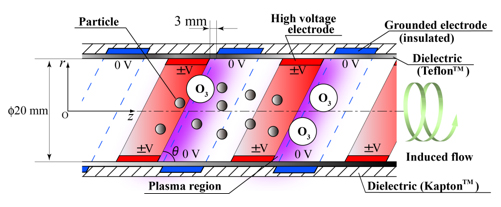

The authors have developed the dielectric barrier discharge tube (hereafter referred to as “plasma actuator tube”) as an innovative technology for ultra fine powder transportation(1). Our developed plasma tube has a dielectric barrier surface discharge (DBD) structure(2) on its inner surface of a tube. The powder inside the tube is transported to axial direction with swirl due to induced flow by plasma actuator effect(3)(4). Furthermore, the powder near the inner electrode takes charge in the discharge and the powder effectively jumps due to electrostatic force to suppress powder accumulation and clogging in the tube. During the discharge, reactive chemical species with high oxidation potential such as OH radical and ozone are generated inside the plasma tube, then the surface purification of the contaminated particles(5) or surface modification of the particles, such as enhancing powder hydrophilic characteristics can be expected by these highly reactive species(6)(7).

In this study, the fundamental characteristics of the plasma actuator tube were quantitatively clarified, such as discharge characteristics, plasma induced flow field visualized by stereo-PIV measurement, powder charging characteristics and powder transfer ratio. The fundamental experimental data were provided for ultra fine powder transportation by developed plasma tube through clarifying the effects of electrode angles and electrical conditions on its fundamental characteristics.

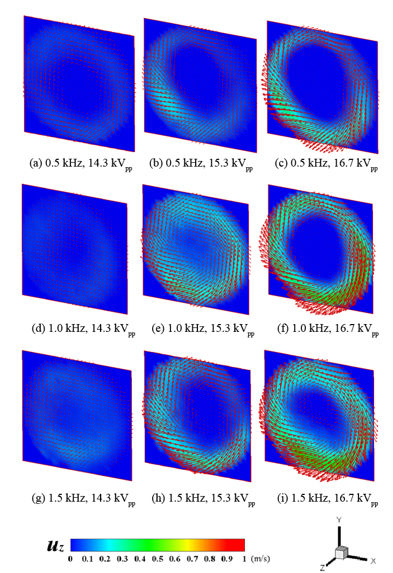

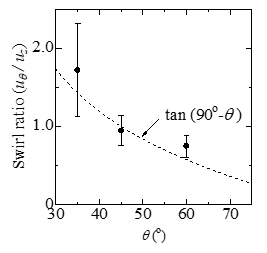

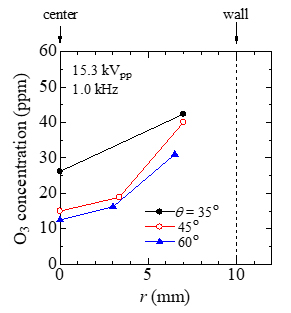

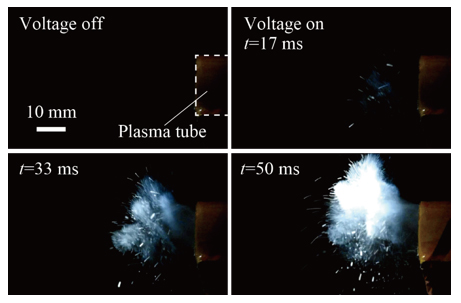

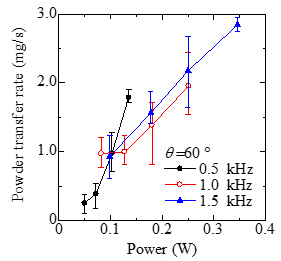

It has been clarified from a stereo-PIV measurement that the plasma induced flow in a plasma actuator tube is a swirling axial flow with very small radial velocity component for small consumption power. The flow is induced only in the vicinity of inner tube wall where plasma is generated. The swirl ratio depends on electrode angle and the swirl ratio decreases with electrode angle. The concentration of generated ozone is the highest near the inner tube wall and it defuses toward the center of the tube. The ozone concentration becomes more uniform in the cross section of the tube for smaller electrode angle with increasing swirling ratio, i.e. longer residence time of the induced flow. Lastly, the dispersed powder transportation by plasma tube has been quantitatively evaluated using alumina powder with average diameter of 30 nm. The powder transportation rate increases with plasma power consumption. The powder can be transported at 2.8 mg/s at consumption powder of 0.35 W for the transportation distance of 100 mm using a plasma tube with electrode angle of 60o.

Keywords

Nano powder transportation, Plasma actuator, Electrostatic mixing, Dielectric barrier discharge

Figures

|

Fig. 1 Cross-sectional view of the developed DBD plasma tube. |

|

| Fig. 2 Three dimensional time averaged induced flow velocity vectors and axial flow velocity distribution measured by stereo-PIV at 2 mm downstream of the tube outlet for the electrode angle of 45o. |

|

| Fig. 3 Correlation between electrode angle and swirl ratio of the discharge induced flow for 16.7 kVpp at 1.0 kHz. |

|

| Fig. 4 Radial distribution of ozone concentration at 5 mm upstream front the tube outlet. |

|

| Fig. 5 Photo of alumina powder transportation by plasma induced internal flow. |

|

| Fig. 6 Powder transfer rate for consumption power. |

References