Newsletter 2012.9 Index

Theme : "Flow in Fuel Cells"

| Back | |

Numerical simulation and evaluation for developing next generation fuel cells

|

Abstract

Fuel cell has much advantage to be expected as a next power generation device for FCV (fuel cell vehicle), electric power source in portable devices, and household power generation device. For FCV, PEFC (polymer electrolyte fuel cell) is promising fuel cell because of its load following capability and quick start-up. However, SOFC (solid oxide fuel cell) can be operated at high temperature with a variety of fuels, including pure hydrogen, hydrocarbon, carbon monoxide, or mixtures of these gases. SOFC is suitable device for stationary system to generate electrical power with high efficiency compare with PEFC. Concerning PEFC, there is a critical issue that generating water often prevents smooth electrochemical reaction without water management. Depending on material property and system structure, robustness for water management receives much amount of effect from power generation. Likewise, SOFC which has very thin solid electrolyte can not endure large heat deformation and rapid heat cycles. To keep lower electrical resistance in thin electrolyte, cell design and operating condition should be improved at planar type SOFC. In this letter, some approach with numerical study for resolving problems of each fuel cell is discussed.

Key words

Numerical study, Polymer electrolyte fuel cell, Solid oxide fuel cell

Figures

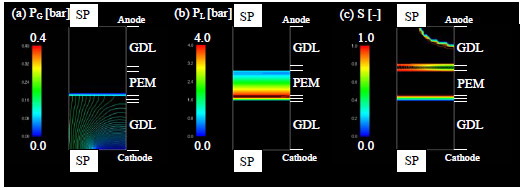

Fig. 1 Water distribution in cathode microporous layer added PEFC operating at high current density, (a) water vapor pressure, (b) liquid water pressure, (c) liquid water saturation.

Fig. 2 Schematic drawing of anode supported planar type SOFC system

(left) cross sectional view, (right) top view.

Fig. 3 Methane reforming effect depended on fuel flow rate. Temperature distribution at the boundary of electrolyte and anode.