Newsletter 2016.2 Index

Theme : "The Conference of Fluid Engineering Division"

|

Foam measurement via a single-tip optical fiber probe with surface treatment

|

Abstract

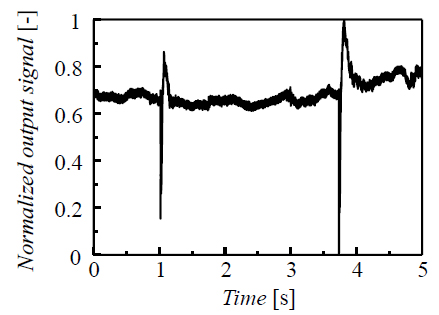

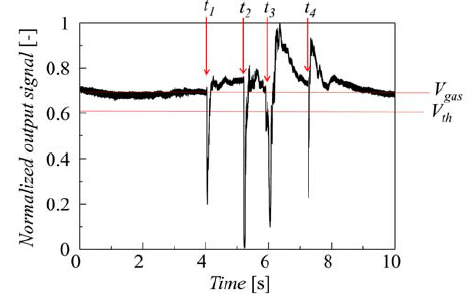

Foam is encountered in many industrial fields, and influences safety and efficiency of a plant such as floatation and wastewater treatment. Conventional foam measurement techniques have hard limitations on their practical use in the real plants. For instance, a transparent vessel is required to visualize foam, or many electrodes are required to estimate average diameter of foam cells. In the present study, we propose a new foam measurement technique using a single tip optical fiber probe (S-TOP). The S-TOP is one of the optical fiber probes uniquely developed in our laboratory. Its optical devices are compact and smart, and it has great heat-resistance and tolerability; hence the S-TOP and its system are appropriate for practical purposes. In addition, the S-TOP possesses satisfactory performance to measure tiny foam cells; however its optical signals are very complex in the foam measurement. The authors have developed a new 3D ray tracing simulation to analyze the optical probing signals. Based on the computational results, we needed to find a falling signal in order to detect the contact of cell’s film and the S-TOP. Furthermore, we carried out two kinds of experiments; the one was an experiment of two thin soap films, and the other was an experiment of dense foam. A problem that foam cells were broken by touching the S-TOP arose. In these experiments, the surface of the S-TOP was changed to be hydrophilic by the surface treatment in order to prevent the foam burst. We obtained a result that the average chord length through the S-TOP measurement is 8.89% less than the average equivalent diameter through the visualization.

Key words

foam, measurement, chord length, single tip optical fiber probe, ray tracing simulation

Figures

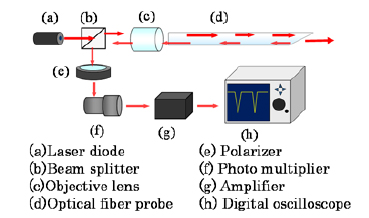

Fig. 1 Optics of the S-TOP.

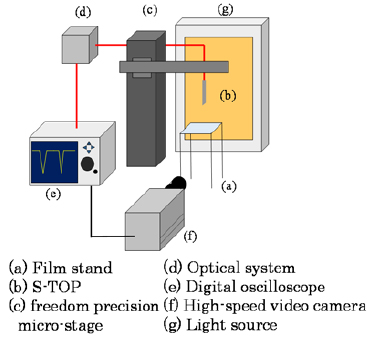

Fig. 2 Experimental setup.

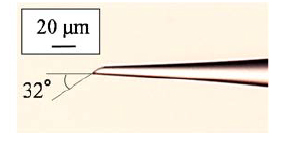

Fig. 3 Micrograph of the S-TOP.

Fig. 4 Output signal of the piercing a film by the surface treated S-TOP.

Fig. 5 Output signal of the foam measurement.