Newsletter 2021.11 Index

Theme : "Mechanical Engineering Congress, 2021 Japan (MECJ-21)”

Workshop on Experimental Fluid Dynamics (EFD)

|

Turbulence of viscoelastic fluid-from practical examples to turbulent coherent structure

|

Abstract

It is known that when a surfactant or water-soluble polymer is added to water, the fluid becomes viscoelastic and the turbulent friction drag is greatly reduced due to the Toms effect. In this report, I will introduce examples of practical research and basic research on the Toms effect.

We conducted demonstration test aimed at saving energy in building air conditioning systems. 0.5% of surfactant (LSP-01A) was added to the amount of circulating water of the Sapporo City Hall air conditioning system, and the pump rotation speed was adjusted by the inverter. As a result, we succeeded in reducing power consumption by 65%.

It was found that the fluid friction resistance of the flat plate can be reduced by 15-20% by applying a water-soluble polymer mixed with the hull paint and gradually eluting it. In a basic experiment in which a polymer solution was dosed from the wall surface instead of hull paint, it was demonstrated that a drag reduction rate of 30% or more could be obtained.

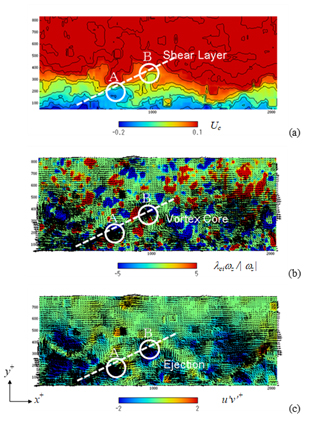

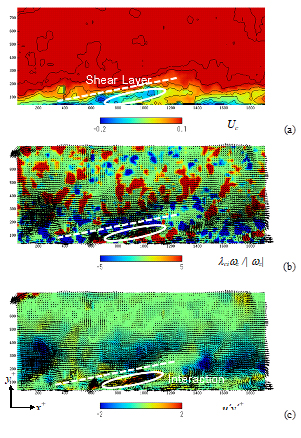

In a basic study simulating the use of polymer-containing hull paint, PIV was used to observe the coherent structure of turbulence near the wall surface where the polymer was dosed. Fig. 1 shows the instantaneous velocity with Galilean decomposition (a), swirling strength (b), and Reynolds shear stress (c) in the water flow, and Fig. 2 shows the results of (a), (b) and (c) in the case of polymer dosing. As a result of the comparison, it was clarified that the water-soluble polymer solution supplied from the wall surface strongly affects the coherent structure of the wall turbulence, suppresses the Reynolds shear stress, and reduces the wall friction resistance.

Key words

Viscoelastic fluid, Drag reduction, Air conditioning system, Ship, Coherent structure, Polymer, Surfactant

Figures

|

|

| Various analyses for instantaneous velocity distribution. (a) Galilean decomposition, (b) swirling strength, (c) Reynolds stress normalized by the frictional velocity. Dashed line represents shear layer observed in (a). Re=4.0×104 | |

| Fig. 1. Water flow (1): Circles A and B are vortex core in (b). Ejection (blue area and velocity vectors head to upper left) is observed in (c). | Fig. 2. Drag reducing flow with polymer blown from the wall (1): Interaction (red area under the shear layer) is observed in (c). |