Newsletter 2022.3 Index

Theme :"The Conference of Fluid Engineering Division (March issue)"

|

The relationship between extensional and shear rheology of power-law fluids

|

Abstract

Understanding the extensional behavior of industrial coating is of great importance of drop-on-demand painting devices for highly-viscous liquid. Since industrial coating elongates during jet injection, it is necessary to investigate the extensional behavior to control the injection volume. However, it is difficult to predict the extensional behavior because industrial coating is a complicated fluid that includes numerous ingredients. On the other hand, shear viscosity measurement devices are widely used. Thus we investigate the relationship between the extensional rheology and the shear rheology of industrial coating to predict extensional behavior from shear viscosity.

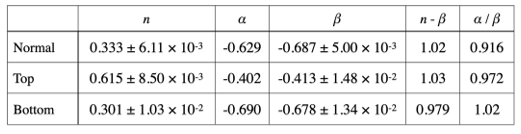

We use capillary breakup extensional rheometer dripping-onto-substrate (CaBER-DoS, Fig.1) for measuring the extensional behavior of industrial coating (power-law fluid). The droplet grows up at the nozzle and then the bottom of the droplet contacts to the glass substrate. The liquid spreads on the glass substrate because of wettability of glass and liquid bridge is formed between the nozzle and the substrate. We capture this filament thinning by using a high speed camera. The extensional viscosity can be obtained from the filament thinning. Also we measure the shear viscosity by shear rheometer.

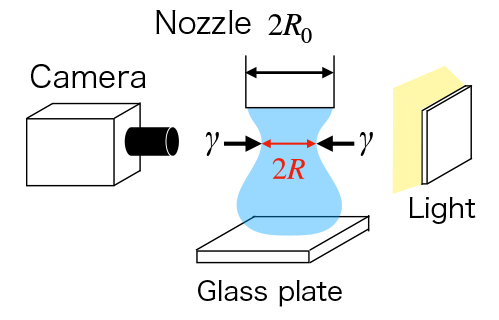

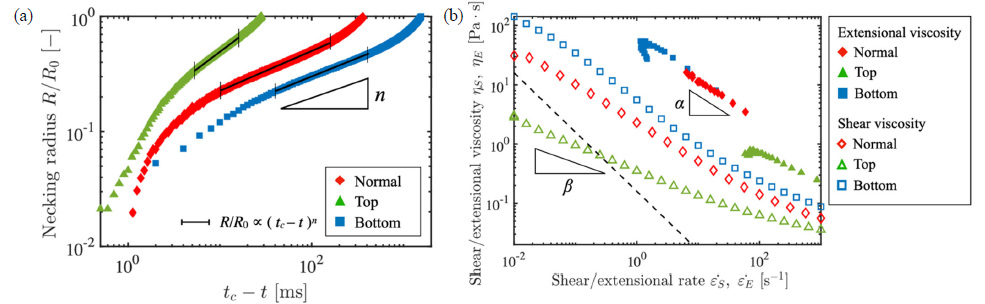

In the case of coating, the time evolution of neck radius of liquid threads (extensional behavior)(Fig.2(a)) and the shear and extensional viscosity change caused by the shear and extensional rate change (Fig.2(b)) can be expressed as power law. The power-law exponents of the extensional viscosity α and the shear viscosity β have almost the same values (Table 1). Moreover, the relationship between the power-law exponents of necking radius n and the both viscosities α, β is n – α = 1, n – β = 1 (Table 1). These relationships are proved not only experimentally but also theoretically. The results suggest that the extensional behavior can be predicted from shear rheology, which is important for the practical application of drop-on-demand painting devices.

Key words

CaBER-DoS, Extensional rheology, Shear-thinning, Coating.

Figures

Figure 1 Experimental setup for the measurement of extensional rheology.

Figure 2 Image sequences which show a filament of coating.

Table 1 Values of the exponents.